| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : WC-CO-CR

Model Number : WC-CO-CR

Place of Origin : China

Certification : ISO9001:2015

MOQ : 50kgs

Price : $48-55/kgs

Packaging Details : 50kgs/Drum

Delivery Time : 7-10days

Payment Terms : T/T at sight

Supply Ability : 10tons/Month

Flowability : Free-flowing Powder

Manufacture : Agglomerated And Sintered

Apparent density : 2.9 – 5.8 G/cm3

Chemistry : 86WC 10Co 4Cr

Classification : Carbide, Tungsten-based

Process : HVOF, Atmospheric Plasma Or Combustion Powder Thermospra

Morphology : Spheroidal

Corrosive wear resistance : Corrosive Wear Resistance

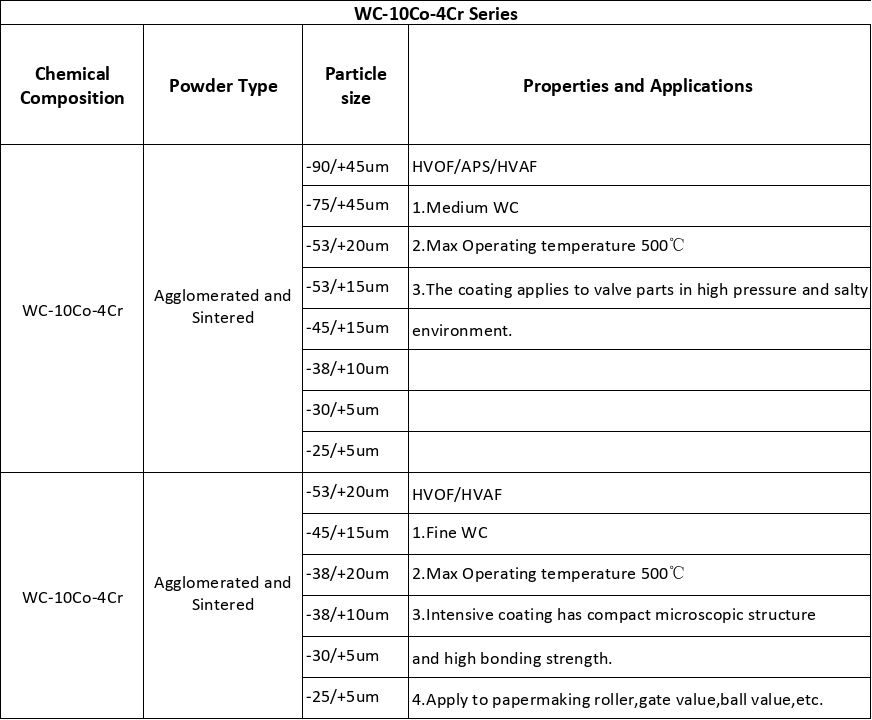

The products are specifically designed for users who require both wear and corrosion resistance. The materials possess 86% tungsten carbide, forming a hard material, as well as a cobalt-chromium matrix which serves as the binder for the carbide particles. Chromium in the matrix also contributes to the product's corrosion resistance. The fine carbide grains creates abrasive, erosive, and fretting wear properties.

Thermal sprayed coatings of these products are quite viable alternatives to hard chromium plating, as they offer excellent wear and corrosion resistance. The coatings can be ground and superfinished to ultimately replicate the effect of chromium plating. High Velocity Oxy Fuel (HVOF) coatings also provide density, strong bond strengths, and smoothly assprayed surfaces. This is useful for applications where grinding cannot be done or is unnecessary.

Thermal Spray Powders are widely used in coating materials, such as WC-CO-CR.

The WC-CO-CR thermal spray powders have the model number WC-CO-CR and are certified by ISO9001:2015.

The minimum order quantity is 50kgs, and the price range is from $48-55/kg.

The packaging is 50kgs/Drum, and the delivery time is 7-10days.

The payment terms are T/T at sight, and the supply ability is 10tons/Month.

The manufacture of these thermal spray powders is agglomerated and sintered, and the process used is HVOF, atmospheric plasma or combustion powder thermospra.

The morphology of the powder is spheroidal, and the apparent density is 2.9 – 5.8 G/cm3.

The chemistry of WC-CO-CR is 86WC 10Co 4Cr. HVAF WC-CO-CR thermal spray powders are an ideal choice for coating materials.

Brand Name: Boda materials -WC-CO-CR

Model Number: WC-CO-CR

Place of Origin: China

Certification: ISO9001:2015

Minimum Order Quantity: 50kgs

Price: $48-55/kgs

Packaging Details: 50kgs/Drum

Delivery Time: 7-10days

Payment Terms: T/T at sight

Supply Ability: 10tons/Month

Chemistry: 86WC 10Co 4Cr

Morphology: Spheroidal

Corrosive wear resistance: Corrosive Wear Resistance

Apparent density: 2.9 – 5.8 G/cm3

Process: HVOF, Atmospheric Plasma Or Combustion Powder Thermospra

We understand the importance of having expert technical support and services to ensure that your thermal spray powders are used in the most efficient and effective manner. We are committed to providing our customers with a comprehensive suite of technical support and services to meet their needs.

Our technical support team is available to answer any questions about our thermal spray powders and offer guidance in the selection and application of the product for the best results. We also provide in-depth technical training on thermal spray powders and their application. This includes topics such as powder selection, application techniques, and troubleshooting.

We also provide a range of services to ensure that our customers get the best performance from our thermal spray powders. This includes on-site visits to assess the project and provide technical advice, installation and commissioning services, and preventative maintenance plans. We also offer a range of custom-developed products and services to meet the specific needs of our customers.

Thermal spray powders are typically packaged in 25-50 pound drums, depending on the powder type and size. The drums are sealed with a lid and secured with shrink-wrap to ensure the powder is free from any contaminants. The drums are then securely palletized and shrink-wrapped for shipping.

The palletized drums are shipped via truck, rail, or air freight, depending on the customer's requirements. Shipping is always tracked and traceable, and customers will receive the tracking information once the shipment has been sent out.

|

|

Corrosive Wear Resistance WC-10Co-4Cr Agglomerated and Sintered Images |